Difficult to choose a printer. Especially in such a zoo that the Chinese and the rest of the world offer. The Chinese, of course, are great, but as a rule, prefabricated models of printers require constriction of all pre-assembled units. Remember this - you bought a Chinese printer, stretched out all the assemblies that came assembled! Otherwise, during the operation of the 3D printer, you will stumble upon problems that it was easier to prevent by tightening before assembly and not waste filament (the plastic you print with) getting a half-printed part. There were cases about them at the end.

Now is the time to ask yourself the question, why do you need a 3D printer? What will I print on it?

I bought myself a printer to understand what it is. So to speak, to feel it with your hands and in the process of operation it gradually began to come to the understanding that this is a lethal thing. All sorts of cubes, knives, pistols were immediately printed. Very quickly, the first batch of filament ended, I took, in my opinion, 3 coils and one came in the kit. I also realized that the dimensions of the table in x, y, z are important. Yes, he did not show which one he bought, here.

In general, I am satisfied, the model is semi-professional, there are cockroaches, they usually come with all printers and are almost the same. You get used to the printer, I think if I were from another manufacturer, I would also praise. Well, like all manufacturers, there are always flaws. The bottom box is completely closed (there is a hole for the fan, but a small one), what I did at the very beginning, I put the 120 fan inside, screwed it to the bottom cover, pre-drilling holes in it, just above the driver board. They get very hot and if you print for a long time, you can burn them. There is another joke, also common, the part sometimes peels off during the printing process, even with adhesion, but this is solved by simply buying a glue stick (the usual one is water-soluble) and smearing the table before printing, it is checked - it works. Me, it seems, it still depends on the filament, the one that came with the kit, even without adhesion, did not fall off. I read also recommend changing the table to glass, like it does not scratch and the filament holds well, but I haven’t gotten to that yet. I'll tell you right away buy a set of nozzles for the printer and just in case cleaning needles. I bought 35 nozzles for 500 rubles, 😊 have already changed 3. The filament may not be of good quality. I did not try to clean with needles, but there is a kit. It seems like everything, I will gradually add breakdowns and solutions. Now there are a few breakdowns that could have been avoided if ...

At the very beginning, there was one breakdown, the extruder heater was not tightened properly, it just dangled in the hole, I noticed this when I changed the first nozzle. The temperature sensor also almost dangled, but not as much as the heater. Another breakdown just coincided or because of it it was necessary to change the 1st nozzle, if you look at the picture, on a thick transparent cambric in which a filament is stretched. Here it should adhere without a gap to the edge of the nozzle in clause 1.

It was not clear in the instructions that it was necessary to push the cambric, that there were forces, according to the instructions it was not clear why, it was like pushing, I think it is very difficult to do it in assembled form - to remove the gap. What happens: the filament cools down and its diameter, as you can see, is not 1.75, but along the diameter of the nozzle thread, warming up longer and as a result, it settles on the wall with constant heating and cooling, turning almost into glass. When I unscrewed the nozzle I could not pull it out, the whole head had to be disassembled - this clogged the nozzle.

The next breakdown, Daughter asked to print a chest from some fan game. I printed the base of the chest, massive by the way, without any problems, so that you understand the volume of the print, the length of the filament is ~ 78 meters. The cover is ~ 48 meters, so I started printing at night and went to bed. In the morning such a picture, the print is complete!? ☹

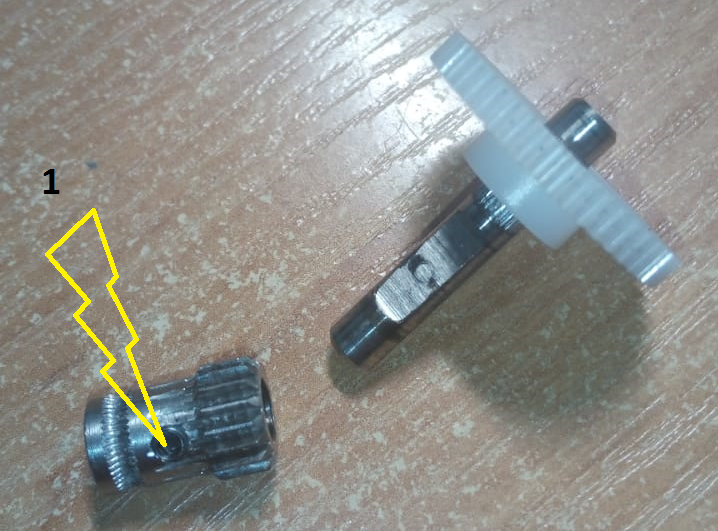

As it is supposed by Google in hand and forward, the main suspicion 1 clogged the nozzle, untwisted it, nothing like that, I was in vain, it is difficult to unscrew the nozzle on the assembled printer. Google again and replies like millet, filament feeder driver, engine, thick filament (I'm using PLA). In fact, everything turned out to be very commonplace and came as usual by accident, pulled on the filament and he almost easily moved, which should not be in the feed, he should hold on firmly. I disassembled the feed and here is the not tightened locking bolt of the gear, see the picture. I myself did not expect to disassemble and stretch to such an extent.

He handed it over, put the seal again, now we look at the picture.

Quite a big detail, but my printer can be larger than 235x235x235, you can print a beautiful vase.

Something like that, thanks for your attention.